To effectively implement and fulfill the corporate social responsibility of USI Group, we respond to the United Nations Sustainable Development Goals (SDGs), the global goals of the Paris Agreement, and domestic energy development policy. In 2016, we devise our own energy conservation and carbon reduction management goals, setting a goal to reduce annual electricity consumption by 1%, reduce annual energy consumption by 1.2%, and reduce 1.5% of carbon emmission annually. Taking the industry benchmark as its goal, USI Group actively promotes innovative technologies that conserve energy and reduce carbon emission to mitigate environmental impact.

To this end, Taiwan VCM Corporation established an energy conservation team, to act in accordance to compliance policies and participate in various government’s activities. In 2016, it was awarded the Outstanding Manufacturer for Voluntary Industrial Greenhouse Gas Reduction by the Industrial Development Bureau of the Ministry of Economic Affairs. In 2017, it was awarded the Silver in the Energy Conservation Benchmark Award by the Ministry of Economic Affairs. In 2019, USI Group was awarded the Excellent Award in promoting energy conservation in 2016-2018 by the Bureau of Energy, Ministry of Economic Affairs.

Energy saving and carbon reduction performance in 2021

| Energy saving & carbon reduction

|

Power saving

(Goal 1%) |

Energy saving

(Goal 1.2%)

|

Carbon reduction

(Goal 1.5%)

|

| 1.65% |

0.82% |

0.80% |

Note:

Most of the equipment in Taiwan VCM Corporation have already been upgraded or replaced with energy-efficient equipment. As the result, energy saving rate in 2021 was limited by the number of replaceable equipment remaining.

Energy Management

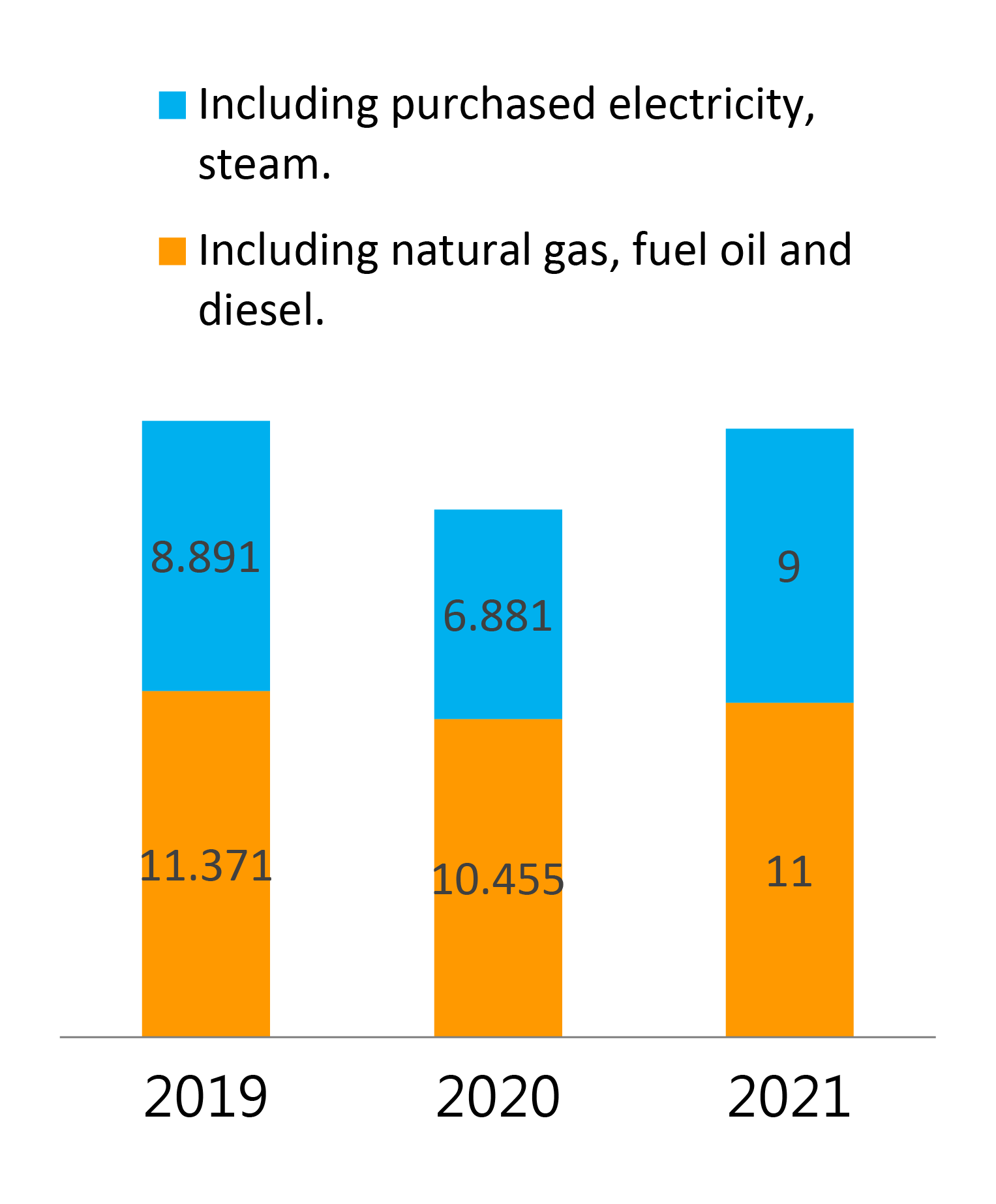

Taiwan VCM Company promotes and implements practical actions to promote energy saving and carbon reduction. The main energy resources are purchased electricity, steam and natural gas.

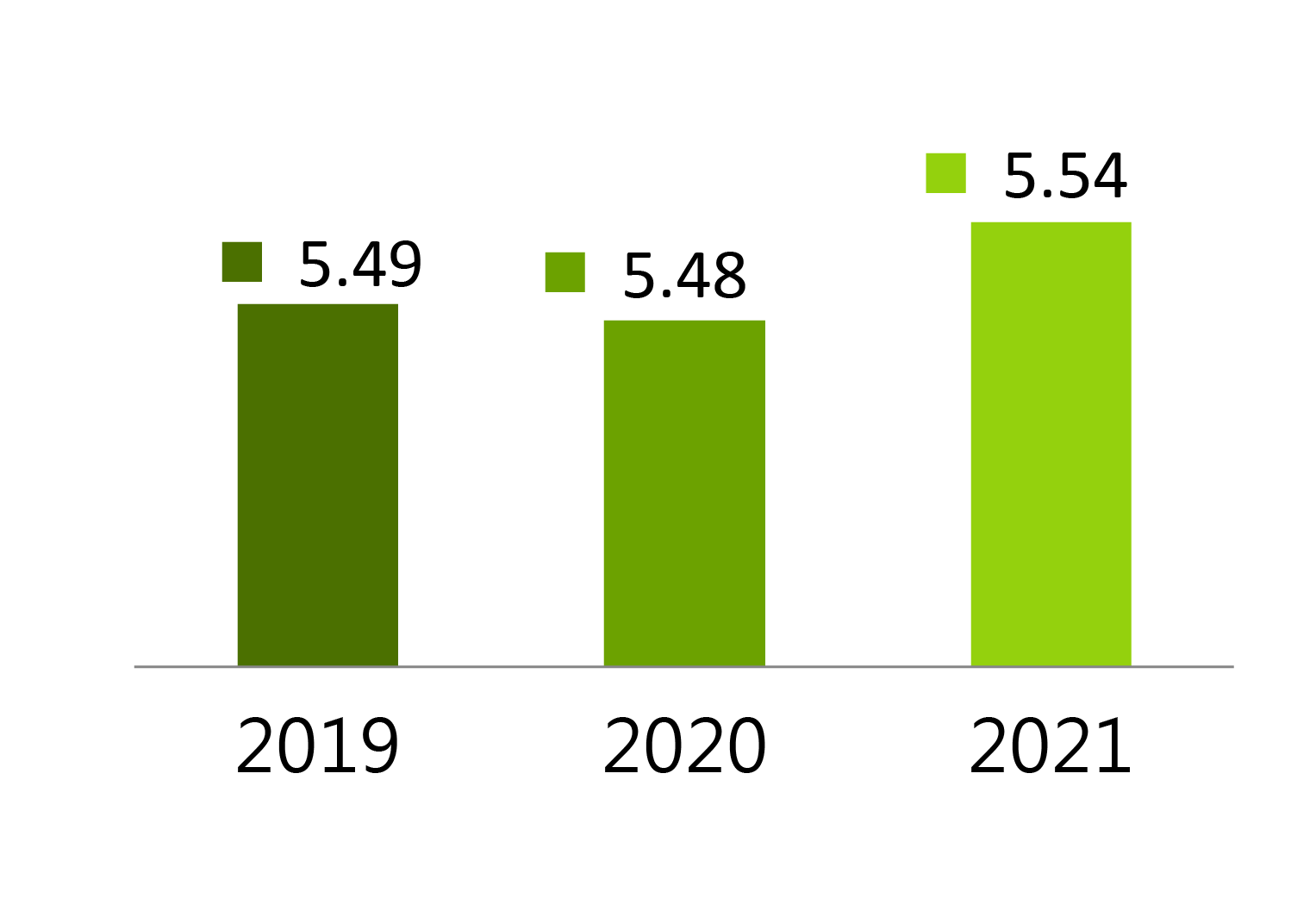

Energy consumption for unit product in the past three years (Unit: GJ / ton)

Note:

Comparing between 2021 and 2020, the increase in energy consumption per unit of product is within ±1.5%.

Energy saving and carbon reduction program in 2021

| Program |

Energy saving

(GJ) |

Carbon reduction

(Ton CO2e) |

- Equipment - Replace Roots blower with turbo-blower / Upgrade the motor of water cooling tower to higher efficiency / Replace circulating fan blades of water cooling tower / Energy-saving coating for cracking furnace.

- In May 2021, applie for Taipower’s planned electricity reduction measures.

- In September and October 2021, respond to Taipower’s Demand Bidding Program to reduce electricity consumption.

|

20,419 |

1,611 |

Note:

1,611 tons of CO2e is equivalent to annual CO2 absorption of four Daan Forest Park. Energy saving performance has improved compared to 2020.

Equipment improvement benefits.

| Program |

As the cracking furnace runs for many years, it leads to poor energy efficiency. Taiwan VCM corporation completed the replacement of equipment in 2017, including the upgrade of refractory materials, changing the design of the burner to save energy, the change of the outer structure of the furnace body and the design of the furnace tube, and the improvement of the furnace tube material. By replacing the cracking furnace with higher efficiency ones, it can reduce energy consumption.

|

| Performance |

On January 15, 2020, Environmental Protection Administration accepted our application for the Greenhouse Gas Transaction Project. The period of calculationis from January 1, 2020 to September 20, 2024.

|

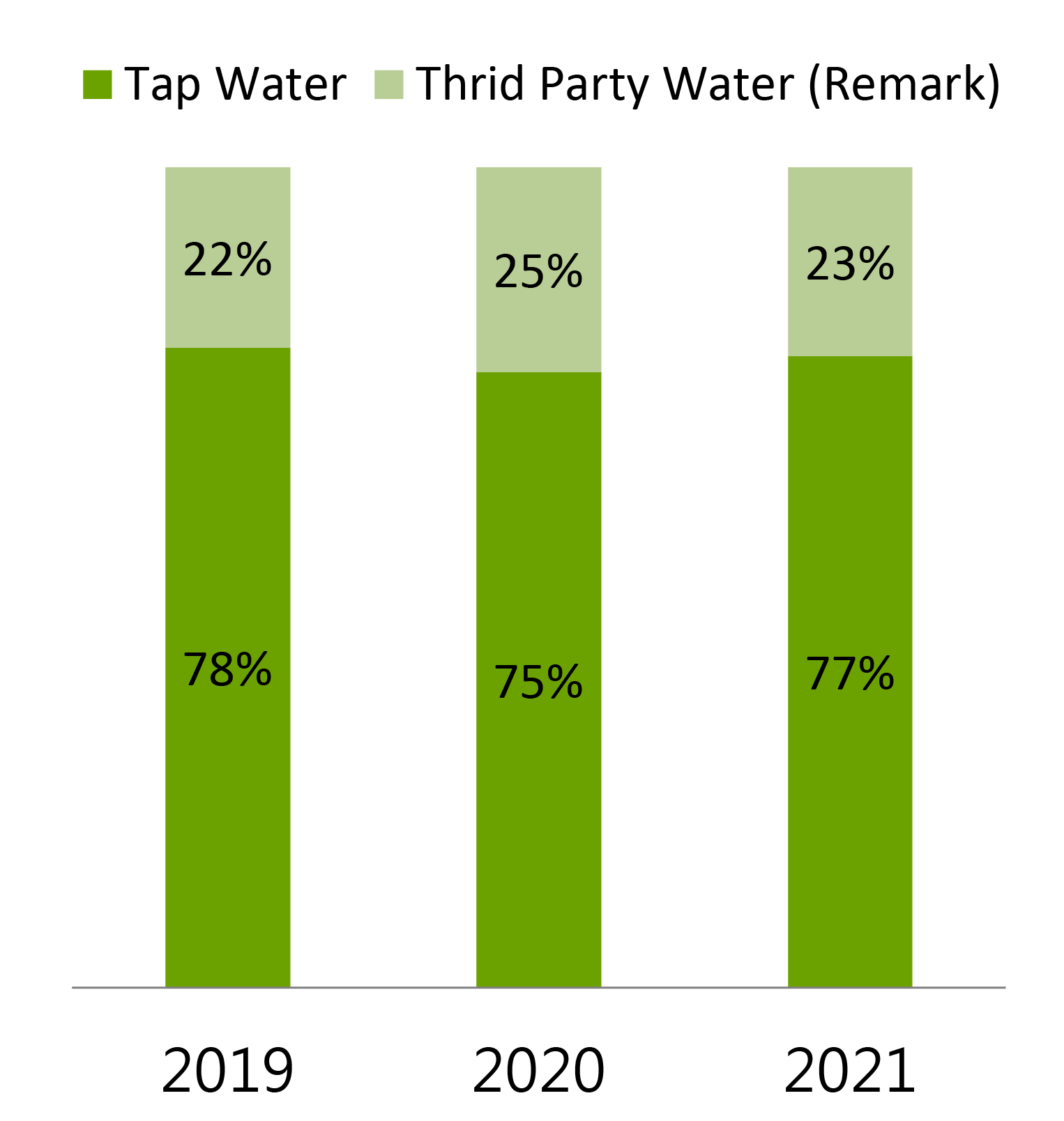

Water Management

In accordance with the USI Group's target of conserving 1% of water per year, we record and monitor our daily, monthly, and annual water comsumption. By researching feasible methods, we adjust the manufacturing process to increase water-saving capability and recycling rate. Regular inspection is conducted to review and propose improvement plans.

The scope of water management in 2021 includes the parent company China General Plastics Corp. (CGPC), TVCM and CGPC’s subsidiary, CGPC Polymer Corp. (CGPC-P) Linyuan Plant, with a coverage rate of 100%

Note: The water used in TVCM’s water cooling tower is recycled water made from HBF of CGPC-P.

Note: The water used in TVCM’s water cooling tower is recycled water made from HBF of CGPC-P.

Greenhouse Gas Management

To effectively control the greenhouse gas emissions of Lin-Yuan plant, the collected data would be examined according to the legislation enacted by the Environmental Protection Agency and the inspection report would be reviewed by a third party periodically.

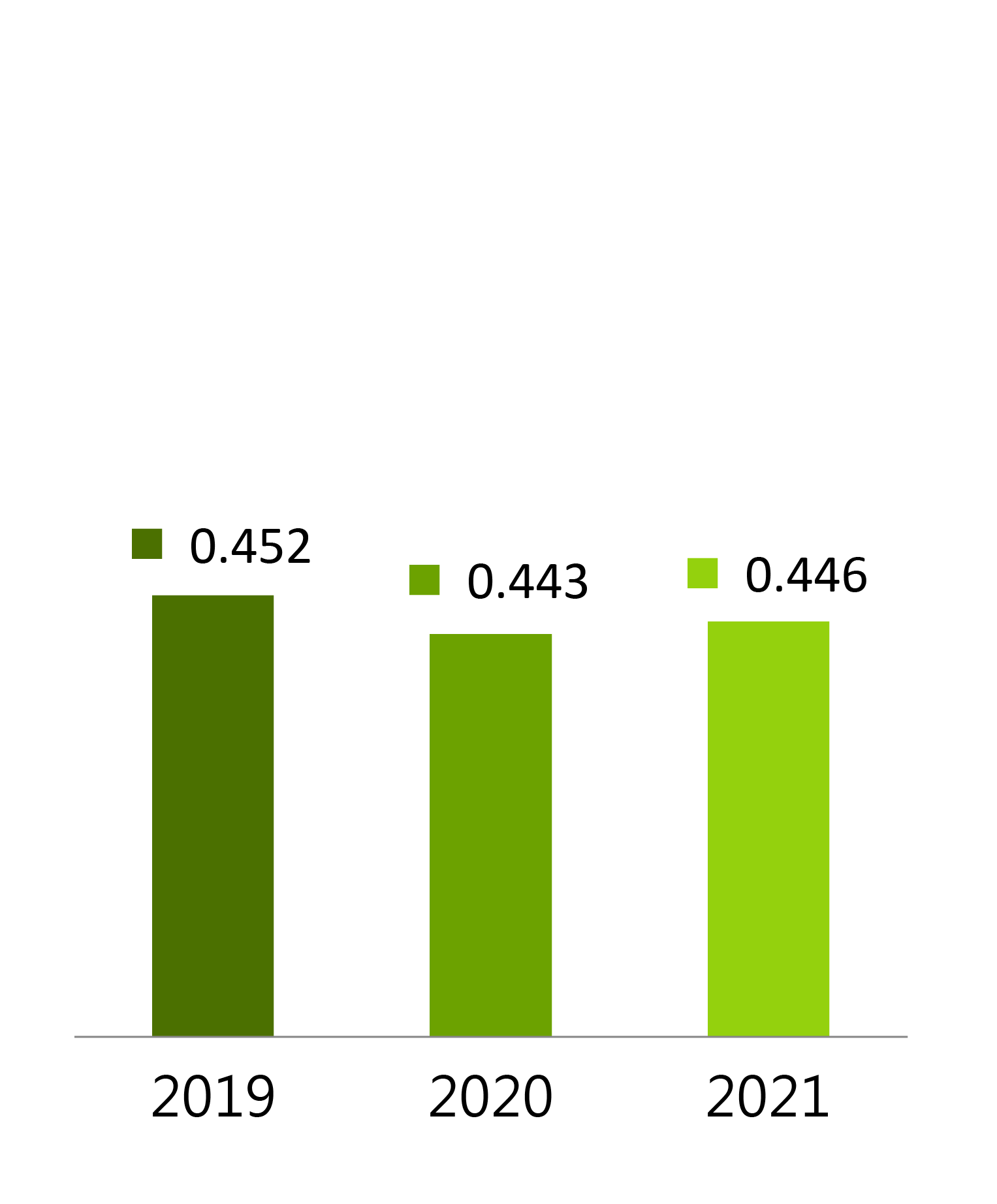

Greenhouse gas intensity of product in the past three years (Unit: GJ / ton)

Note: The target is set at 0.464, and the greenhouse gas intensity of TVCM’s products from 2019 to 2021 has reached the target.

Greenhous gas emission of product in the past three years (Unit: CO2e)

Note: TVCM revised its greenhouse gas emissions in 2020, as the inventory data was obtained after the declaration.